Tubular Motors

In the tubular motor category, we offer two distinct product families:

- Green Drive: For large forces and for 230Vac or 400Vac

- NL Series: For smaller forces and for 24Vdc or 48Vdc

Do you have technical questions or need a quote?

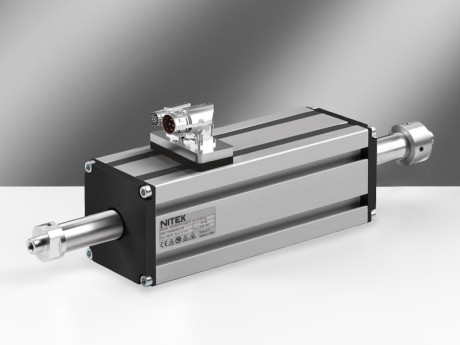

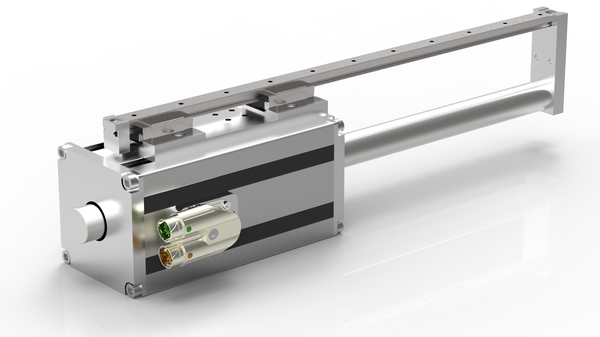

Green Drive Tubular Motors For High Forces

-

DC-link voltages up to 560Vdc - Peak force up to 1,160N

-

Strokes up to 600mm - Optional anti-rotation device

-

Feedback: Quad A/B, Analog Sin/Cos 1Vpp, BiSS

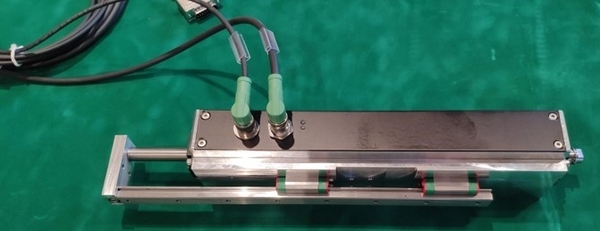

The Green Drive tubular linear motor is a direct drive actuator. The linear motion is generated without ballscrews, belts and or gears. The Green Drive is composed of two parts: the stainless steel slider with holes for payload fixing and the IP65 motor body that contains the coils and the feedback electronics. The slider is guided by high performance sliding bearings. The electronics contains position sensors, temperature sensors, interpolation electronics and motor parameters as an electronic data sheet (EDS).

The Green Drive standard version is available in different sizes up to reach 1,160 N of peak force. All models are available with different strokes and feedback options. Additionally, special models for hygienic applications are available on request.

- Analog SIN/COS 1Vpp, Quad A/B, BiSS-C

- DC-link voltage: 320Vdc or 560Vdc (same winding)

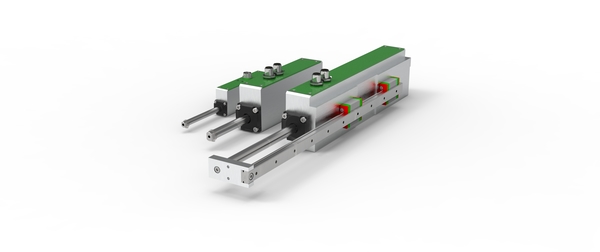

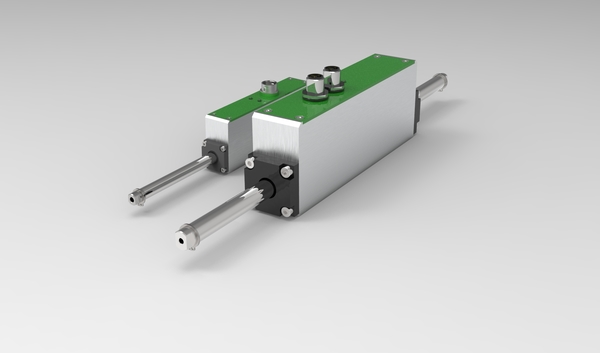

NL Series: Miniature Tubular Motors

-

Motor with optional integrated drive electronics -

Flange dimensions beginning from 15x34mm till 35x63mm -

Force range starts from 0,6 N up to 20 N of continuous force -

Voltage 24 VDC to 48 VDC -

Encoder SIN/COS 1 Vpp

Linear Motors With Integrated Drive Electronics

The miniature linear motors NLI have the same outside dimensions of the standard NL series, including a high-performance servo drive with positioning features and CANopen fieldbus control. The power supply of these motors has a wide range from 24 Vdc up to 48 Vdc. The miniature linear motors NLI with integrated drive electronics are particularly suitable for the replacement of pneumatic actuators, using the same control logic.

Main features:

-

Compact direct drive linear actuator CE certified - Integrated FOC drive and PLC functions: 10 different programmable position tasks with 4 different motion profile options (trapezoidal, triangular, polynomial and sinusoidal)

- Motion control using Digital input 0-24VDC (same as pneumatic cylinder electrovalve control) – plug&play to replace pneumatics

- Motion control using Analog input 0-5VVDC (voltage to frequency control using sinusoidal motion profile)

- 2 Digital Inputs, 3 Digital Outputs to map faults or conditions like in position window

- MODBUS RTU for diagnostic and commissioning

- 24VDC to 48VDC power

- Diagnostic functions: on time, travelled distance in km, number of performed cycles, load on the motor and temperature (512 minutes log inside the motor)

- Interpolated motion using digital input trigger

- Status leds

- Accessories for antirotation mechanics (pneumatic brake option for vertical axis)

- Competitive price (minimum delta from encoder only motor solution)

Do you have technical questions or need a quote?

Overview of Important Parameters

| Motor Code |

Rated Force |

Peak Force |

Actuator length |

|

LH |

max. effective Stroke |

Datasheet | ||

|

Standard |

|

0,6 | 3,9 | 55 | 15 | 34 |

|

||

|

|

1,08 | 7,02 | 91 | 15 | 34 | ||||

|

|

4,8 | 31,2 | 118 | 20 | 40 | ||||

|

|

8,64 | 56,16 | 178 | 20 | 40 | ||||

|

|

21,12 | 137,28 | 185 | 35 | 63 | ||||

|

|

38,016 | 247,104 | 305 | 35 | 63 | ||||

|

Integrated |

|

4,8 |

31,2 |

118 |

15 |

|

|

800 |

|

| 40 | 49 | ||||||||

|

|

8,64 | 56,16 | 178 | 15 | 40 | 49 | 800 | ||

|

|

21,12 | 137,28 | 185 | 20 | 63 | 90 | 1500 | ||

| NLi120X | 38,016 | 247,104 | 305 | 20 | 63 | 90 | 1500 | ||

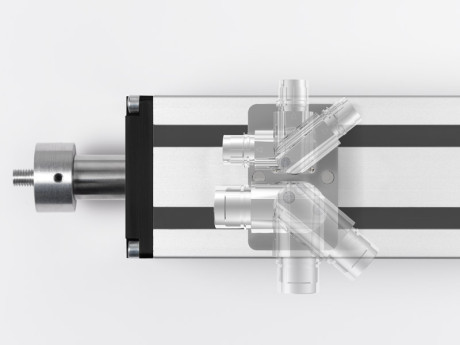

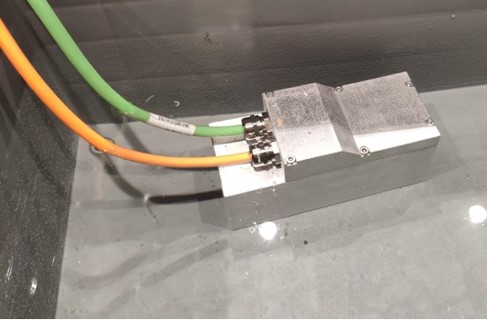

Food-grade i.e. Hygienic Tubular Linear Motors

The tubular motors (linear motors) are also available as a food-safe i.e. hygienic version. See picture on the right.

- IP69K i.e. suitable for high-pressure cleaning and washdown

- With IP69K food-grade cable glands (clearly visible in the picture) either nickel-plated or made of stainless steel

- Housing of the coil unit made of stainless steel or alternatively aluminium with GHA coating (antibacterial due to silver ions, less expensive than stainless steel). An additional advantage of aluminium: better transfer of dissipated heat from the electric coil unit.

- Polymer bushing from IGUS®, certified for the food industry (FDA)

- Magnetic forcer (= push rod or piston rod) made of stainless steel

- Bus voltage 320Vdc or 560Vdc

- Built-in linear measuring system consisting of analogue Hall sensors

- Repeatable positioning accuracy approx. ±150µm

Do you have technical questions or need a quote?

Application Range of Linear Motors / Tubular Motors

Food Processing Industry

- Horizontal or vertical packaging

- Handling of food and / or its packaging

- Machines for the production of dairy products

- Dosage of food

Beverage Industry

- Machines for the production and printing of capsules and lids / closures

- PET Bottle Caps

- Stretch blow molding of PET bottles

- Handling and sorting of PET blanks

- Filling machines

Pharmaceutical Industry

- Handling and / or filling of bottles

- Counting, weighing and sorting of tablets

- Blister Packaging

Wood Processing Industry

-

Cutting and handling of wooden boards - Edge processing of wooden boards

Paper / Textile Industry

- Handling and folding of paper (toilet and food paper)

- Replacement of pneumatic drives for the following functions: stacking, separating and pushing

- Furniture packaging

- Diaper Machines

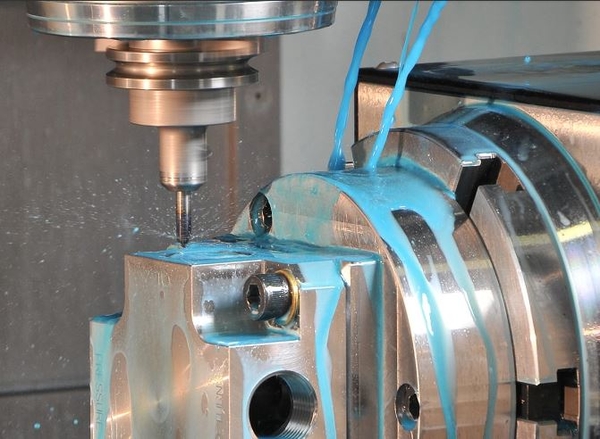

Machine Tools

- Electric Discharge Machines

- Machining centers

- Handling of mechanical parts and tools

Advantages of A Linear Motor Over A Pneumatic Drive

The linear motor has an excellent precision and operates much more quietly than a pneumatic drive. Compared to conventional products, the tubular linear motor scores points above all with its excellent performance in the following areas energy saving, speed and acceleration.