Linear Motors Used As Direct Drives

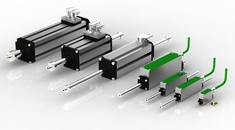

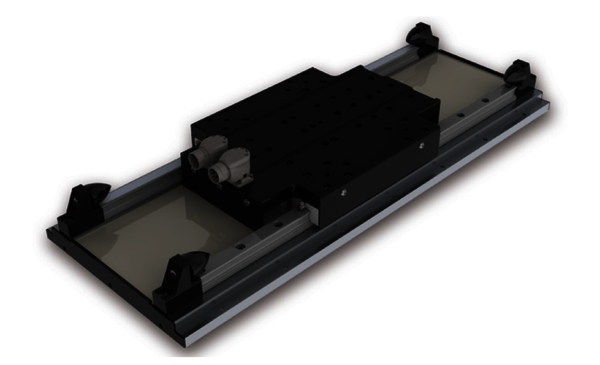

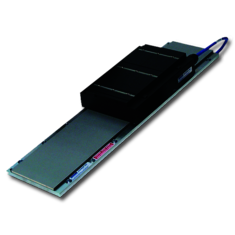

Increasing requirements regarding dynamic behaviour, accuracy and smoothness caused a technology shift also in the area of linear motion, namely the shift towards direct drive motors. As in rotary direct drive technology today there are linear direct drive motors where the mechanical load is directly connected to the moving part of the motor - without any further coupling. This stiff connection offers the same advantages as in rotary direct drive technology and allows for completely new machine designs.

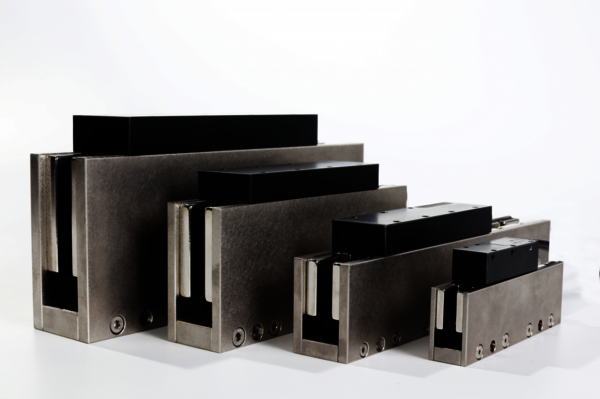

Compared to linear motion systems driven by rotary motors (see Actuators), direct drive linear motor systems do not have a principle limitation in length. The stationary magnet assembly can be stacked together from standard modular profiles to any demanded length. Because the moving part (winding) can be used for any desired move length, there is no change of performance depending on the length.

Leadscrew system in contrast do have critical limitations regarding speed and the inertia grows with the length of the leadsrew and therefore the stroke. Limitations in speed, high inertia and low stiffness still are the main disadvantages of other technologies compared to direct drive linear motor systems in longer stroke applications.